EGG CLASSIFICATION AND PACKAGING

✓ Capacity: Maximum 36.000 Eggs / Hour

✓ Possibility of classification in 4 dimensions based on weight

✓ 0.1 g weighing accuracy

✓ Easy adjustment of classification groups with the help of touch panel

✓ Digital weighing system

✓ Ease of use with color touch screen

✓ Stainless steel body

✓ Possibility to keep 50 different poultry groups in memory

✓ 6 rows of egg movement corridors

✓ Line out: 3 floors

✓ Power: 380V-3-phase-AC, 50/60 Hz

✓ Energy: 2,4 Kva

ZRM-70

✓ Capacity: Maximum 70.000 Eggs / Hour

✓ Possibility of classification in 5 dimensions based on weight

✓ 0.1 g weighing accuracy

✓ Easy adjustment of classification groups with the help of touch panel

✓ Digital weighing system

✓ Ease of use with color touch screen

✓ Stainless steel body

✓ Possibility to keep 50 different poultry groups in memory

✓ 12 rows of egg movement corridors

✓ Line out: 4 floors

✓ 380V-3-phase-AC, 50/60 Hz

✓ Energy: 3 Kva

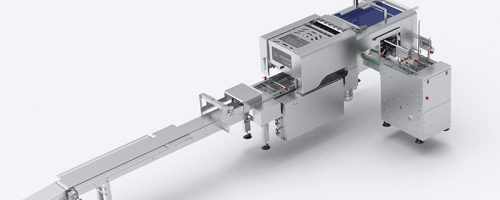

ZR-36

✓ Capacity: Maximum 36.000 Eggs / Hour

✓ Smooth egg transition in accumulator control

✓ Packaging Line with / without Viol sensor

✓ Automatic stopping and starting system of egg conveyor coming from the house

✓ Speed control on operator screen

✓ Continuous operation at high speed without any problems

✓ Easy and useful operator screen

✓ All stainless steel

✓ Power: 380V-3-phase-AC, 50/60 Hz

✓ Energy: 1,8 Kva

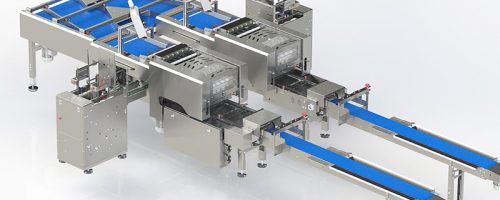

ZR-70

✓ Capacity: Maximum 72.000 Eggs / Hour

✓ Smooth egg transition in accumulator control

✓ Packaging Line with / without Viol sensor

✓ Automatic stopping and starting system of egg conveyor coming from the house

✓ Speed control on operator screen

✓ Continuous operation at high speed without any problems

✓ Easy and useful operator screen

✓ All stainless steel

✓ 380V-3-phase-AC, 50/60 Hz

✓ Energy: 3.2 kVA

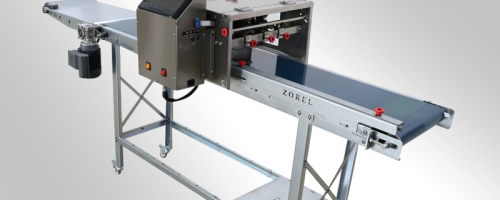

ZRP-506K

✓ Capacity 70.000 Eggs / Hour

✓ Data entry to the machine with numeric and alphanumeric keypad

✓ Automatic printing of production and expiry date.

✓ Logo, Picture etc. printing characters.

✓ 6 x HP-45 printer and cartridge system.

✓ CF card slot

✓ Stainless steel printer unit

✓ Structure preventing tracery from falling

✓ Side barriers for alignment

✓ Portable conveyor structure.

✓ Galvanized conveyor structure

✓ Power supply platform

✓ Longer-lasting cartridges with cartridge protection system

✓ If 6 cartridges write 2 rows, it can write 800,000 eggs.

Z-JET

✓ Average Capacity: 200.000 Eggs / Hour

✓ Easy numerical and alphanumeric data entry thanks to the touch screen

✓ Automatic printing of production and expiry date.

✓ Logo, Picture etc. printing characters.

✓ Stainless steel body.

✓ The number of removable printheads is between 2 and 5

✓ Maximum printing speed;

– Single line printing, min / sec. one

– Double line printing, min / sec. 0.75

– Three lines printing, min / sec. 0.5

– Four lines printing, min / sec. 0.25

✓ Storing text and sign characters in memory, printing from memory.

✓ Cartridge-free use.

✓ Ink filling reservoir. (1.5 liter ink tank)

✓ Easily portable conveyor structure

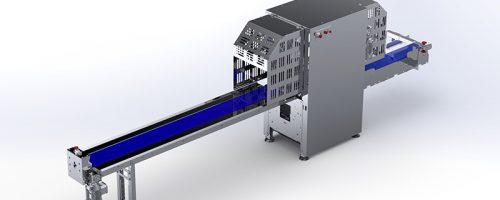

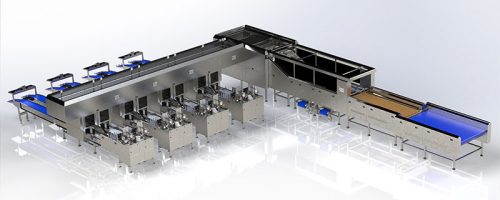

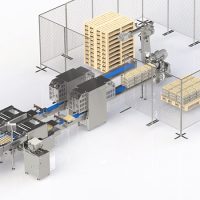

ZX Serisi

✓ Its capacity is 55,000-85,000-115,000 eggs / hour – in 3 different categories.

✓ Number of outputs: Maximum 26

✓ Viol covering feature: Yes

✓ 0.1 gr weighing accuracy

✓ 6 or 12 rows of egg movement lines

✓ Automatic control system from the house to the feeding conveyor

✓ Easy and useful operator screen

✓ Access to all machine settings and information on the operator screen

✓ Continuous and trouble-free operation at high speed

✓ Smooth egg transition in accumulator control

✓ Sending the desired egg weight to the desired packer on the screen.

✓ Stainless steel

✓ It can be washed at any time and cleaned easily.

✓ It has a modular structure.

✓ Attachable packaging line

✓ Easy problem solving without stopping and slowing down the machine thanks to the bypass line in the packaging line

✓ Tracking and directing the stages thanks to smart touch screens

✓ It has a sensitive structure.

EGUSKI ZX SERIES egg grading and packaging machines are produced to meet your demands in the best way. Every detail has been meticulously thought out and equipped with today’s technologies.

EGUSKI ZX SERIES has a sensitive structure. It prevents the eggs coming through the conveyors from contacting each other or with the machine. Thus, the formation of invisible small cracks is prevented.

Eggs with the desired weight can be sent to the desired packers on the operator screen. Thus, the eggs sorted by a sensitive weighing system are packed in the processed viol options.

Thanks to the advanced camera feature of the ZX SERIES, the eggs are separated before they reach the palletizing line if broken, dirty or cracked. Thus, the producer offers the perfect egg to the consumer.

ZX SERIES consists of stainless steel and plastic parts. Everything that comes into contact with the environment and substances can naturally become contaminated over time and contain dust and bacteria. At exactly this point, X SERIES offers you the opportunity to clean and wash in periods you want, thanks to its washable and cleanable feature.

ZOREL ZX SERIES are designed to best meet the increasing capacity, demands and needs of the egg industry.

The ZX SERIES, which has a modular structure, processes the eggs with great precision, with the addition of more packaging lines and more entry rows.

Thanks to the bypass line, any malfunction that may occur in the packaging line can be easily resolved. Thus, your machine will not slow down or encounter problems such as stopping.

Thanks to the smart touch screens, you can easily follow and direct each stage.

Thanks to the carefully thought-out settings, your machine always runs smoothly and continuously at full capacity. EGUSKI works for this.