MANURE DRYING SYSTEMS

Home > MANURE DRYING SYSTEMS

END THE FERTILIZER-BORNE DISEASES!

When un-dried and unprocessed fertilizers are thrown into the soil; soil, groundwater and atmosphere are polluted. In addition, depending on the ambient conditions uncontrolled breeding bacteria produce unpleasant odor in the environment.

In this context, Eguski has completed the R & D studies for poultry farming, which is one of the biggest problems of the poultry companies and which is becoming more important in the new legislation, and also emphasizes the importance of biosafety at the point where it can be adapted to climate conditions, capacity and customer needs with high energy efficiency has developed a new generation fertilizer drying system designed for modular construction.

The system, operating independently of fans in the cluster to create airflow, using the pressure chamber created by its own fans, has been relieved of the necessity of being installed in the farms’ fans. By transferring the fertilizer poultry to the central drying system with conveyor belt systems, drying away from the living areas is prevented and disease formation caused by fertilizers is prevented.

Developed new generation drying technology;

- It removes ammonia formation from the middle by preventing airborne bacteria growth with high air velocity.

- Odorless drying is achieved by inhibiting ammonia discharge.

- Compared to fermented and dried fertilizers, high calorific value fertilizers are obtained in which the amount of nitrogen, carbon and hydrogen is not reduced.

- The obtained fertilizer can be easily used as an energy source in various combustion systems.

- Fertilizer can be dried to the pellet and granulate at a suitable moisture content, thus providing commercial profit.

- Drying system can be produced in modular structure depending on different customer needs and climate conditions.

- Completes the drying of the fertilizer in 24 hours and provides energy and workforce profit in operating costs.

Technical specifications;

- The system’s heating energy can be supplied by steam or hot water.

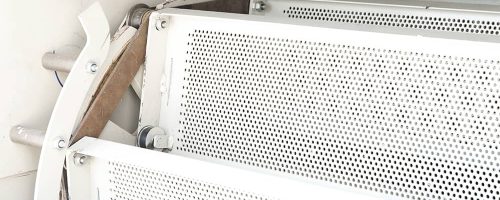

- The system is made entirely of corrosion resistant material.

- Up to 15-18 cm of fertilizer can be loaded on the pan.

- Loading and unloading operations are performed with conveyor systems.

- The industrial structure of the dryer allows the use of the equipment without external intervention.

- The system can operate completely automatically.

- Radiator can be selected according to cold climate conditions.